Non-metallic mineral grinding mill is widely used in metallurgy, building materials, chemicals, mining and other sectors. According to the working principle, processed fineness and capacity, grinding mills can be divided into many types, such as Raymond mill, vertical mill, superfine mill, ball mill and etc. The mill production efficiency directly affects the user’s profit, in this article we will discuss about the factors that affect the mill production efficiency.

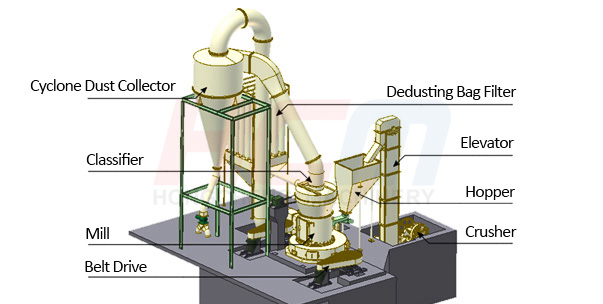

Raymond mill structure

Factor 1: Material hardness

Material hardness is an important factor, the harder the material, the more difficult it is to process. If the material is very harder, then the mill grinding speed would be slower, the capacity would decreased. Therefore, in the daily use of the equipment, we should strictly follow the mill instructions to grind the materials with appropriate hardness.

Factor 2: Material humidity

Each type of grinding equipment has different requirements for the humidity content of the material, as humidity content will affect the production efficiency. When the materials have higher humidity, they are very easy to adhere in the mill, and they will block during the feeding and conveying, resulting decreased capacity. And it will block the circulating air duct and the discharge port of the analyzer. Generally, the material humidity can be controlled through drying operation before grinding.

Factor 3: Material composition

If the raw materials contain fine powders, then they would be easy to adhered to affect transportation and grinding efficiency, so we should screen them in advance.

Factor 4: Finished particle size

If you require very fine particle size, then the grinding capacity would be lower correspondingly, this is because that the material needs to be ground in the mill for a longer period of time, then the capacity would be reduced. If you have high requirements for fineness and capacity, you can choose HC super large grinding mill for high throughput rate, its maximum capacity is 90t/h.

HC Super Large Grinding Mill

Max feeding size: 40mm

Capacity: 10-90t/h

Fineness: 0.038-0.18mm

In addition to the above factors, there are also some other factors that will affect the production efficiency, such as improper operation, insufficient lubrication, etc. If you want to know more about the Mineral Mill, please contact us directly.

Post time: Dec-13-2021